Robovision

Robovison and IDLab have produced a working robot for the automotive sector that is environmentally aware and recognizes its human co-workers’ faces and language preferences. One of Robovision’s star performers is Klebor, a robot that works on the Brussels production line of Volkswagen/Audi. Developed as part of the iMinds ClaXon project — drawing on expertise from robotics and artificial intelligence (AI) specialists at the University of Ghent’s world-renowned IDLab — Klebor operates in full awareness of its surroundings and does not need to be separated from humans with fences. It speaks three languages, can recognize its human co-workers’ faces and addresses them in their language of choice, and can even infer what action to take when an operator gestures without using words. For a machine to work with non-uniformity data requires deep learning: abstracted, multi-layered, non-linear data processing based on real-world inputs. Robovision’s CEO says this could not have been achieved without the help of iMinds – IDLab and its researchers’ knowledge on GPUs. It’s a great example, he says, of iMinds’ critical role in bringing academia and industry together in Flanders.

“Robovision’s business is all about disruptive technology. We want to look differently at situations — to go into a niche, analyse how it’s been done for decades, and come up with a way of doing nobody has thought of before. In fact, if someone else can do it, we’re not interested.”

FORWARD project

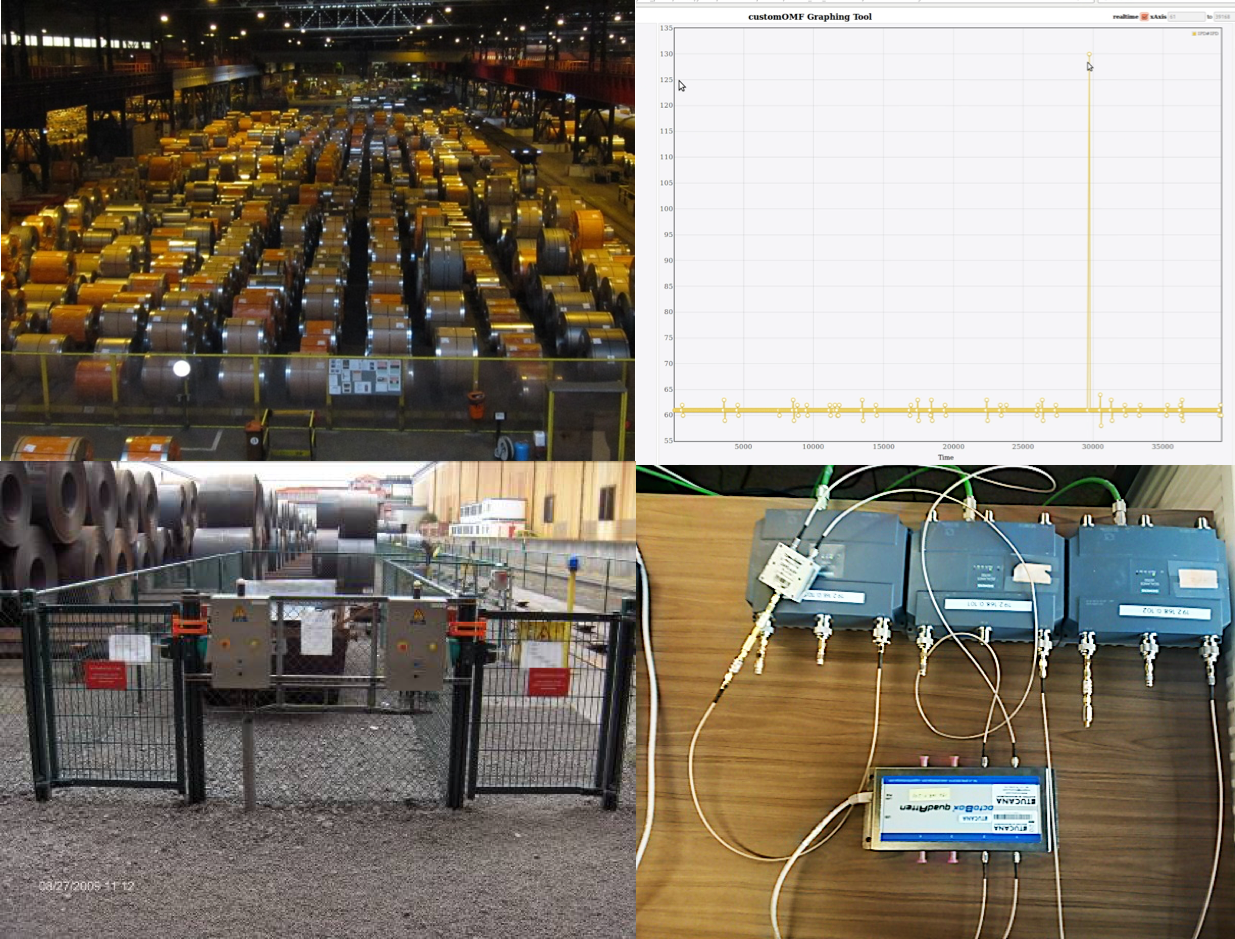

Wireless communication will become increasingly important for the welfare of industrial processes, but is challenging at the same time. Since most of the industrial environments are large areas like warehouses or production halls, multi access point (AP) systems must be used to provide proper coverage across the entire area and mobile devices must seamlessly switch from one AP to another while moving around.

Within the FORWARD project, iMinds and industrial partners (Volvo, Arcelor-Mittal, Siemens, Egemin, Excentis) joined forces to dimension and develop flexible and diagnosable wireless solutions in industrial environments in order to enable robust wireless automation and communication. One particular example was the controlled assessment in a lab environment of the handover impact on time-critical PLC traffic, required for safety communication between a safety fence and a moving crane.

“Today, apart from some proprietary extensions, Wi-Fi lacks proper features to deal with time-critical and mobile industrial applications”